UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

(Mark One)

|

☒ |

ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended December 29, 2019

or

|

☐ |

TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from to

Commission File Number 0-31051

SMTC CORPORATION

(Exact name of registrant as specified in its charter)

Delaware

(State or other jurisdiction of incorporation or organization)

98-0197680

(IRS Employer Identification Number)

7050 WOODBINE AVE, Suite 300.

MARKHAM, ONTARIO, CANADA

(Address of Principal Executive Offices)

L3R 4G8

(Zip Code)

Registrant’s telephone number, including area code: 905-479-1810

Securities registered pursuant to Section 12(b) of the Act:

|

Title of each class |

Trading symbol(s) |

Name of each exchange on which registered |

|

Common stock, par value $0.01 per share |

SMTX |

The Nasdaq Global Market |

Securities registered pursuant to Section 12(g) of the Act: NONE

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ☐ No ☒

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes ☐ No ☒

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes ☒ No ☐

Indicate by check mark whether the registrant has submitted electronically every Interactive Data File required to be submitted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit such files). Yes ☒ No ☐

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, a smaller reporting company, or emerging growth company. See the definitions of “large accelerated filer,” “accelerated filer”, “smaller reporting company”, and “emerging growth company” in Rule 12b-2 of the Exchange Act.

|

Large accelerated filer ☐ |

Accelerated filer ☒ |

Non-accelerated filer ☐ |

Smaller reporting company ☒ |

Emerging growth company ☐ |

If an emerging growth company, indicate by check mark if the registrant has elected not to use the extended transition period for complying with any new or revised financial accounting standards provided pursuant to Section 13(a) of the Exchange Act. ☐

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Act). Yes ☐ No ☒

The aggregate market value of common stock of the registrant held by non-affiliates of the registrant was approximately $76.9 million on June 28, 2019 (the last business day of the registrant’s most recently completed second fiscal quarter). For purposes of the foregoing sentence, the term “affiliate” includes each director and executive officer of the registrant and each holder of more than 10% of the registrant’s common stock. This determination of affiliate status is not necessarily a conclusive determination for other purposes. The computation of the aggregate market value of the registrants common stock is based upon the closing price of the common stock as reported on The Nasdaq Global Market on June 28, 2019 (the last trading day of the registrant’s most recently completed second fiscal quarter).

As of March 13, 2020, the registrant had 28,195,300 shares of common stock, par value $0.01 per share outstanding.

Documents Incorporated By Reference: None.

TABLE OF CONTENTS

Annual Report on Form 10-K for the fiscal year ended December 29, 2019

|

PART I |

|

3 |

|

Item 1. |

Business |

3 |

|

Item 1A. |

Risk Factors |

13 |

|

Item 1B. |

Unresolved Staff Comments |

29 |

|

Item 2. |

Properties |

29 |

|

Item 3. |

Legal Proceedings |

29 |

|

Item 4. |

Mine Safety Disclosures |

29 |

|

|

|

|

|

PART II |

|

29 |

|

Item 5. |

Market for Registrant’s Common Equity, Related Stockholder Matters and Issuer Purchases of Equity Securities |

30 |

|

Item 6. |

Selected Financial Data |

31 |

|

Item 7. |

Management’s Discussion and Analysis of Financial Condition and Results of Operations |

33 |

|

Item 7A. |

Quantitative and Qualitative Disclosures About Market Risk |

46 |

|

Item 8. |

Financial Statements and Supplementary Data |

49 |

|

Item 9. |

Changes in and Disagreements With Accountants on Accounting and Financial Disclosure |

49 |

|

Item 9A. |

Controls and Procedures |

49 |

|

Item 9B. |

Other Information |

50 |

|

|

|

|

|

PART III |

|

51 |

|

Item 10. |

Directors, Executive Officers and Corporate Governance |

51 |

|

Item 11. |

Executive Compensation |

53 |

|

Item 12. |

Security Ownership of Certain Beneficial Owners and Management and Related Stockholder Matters |

62 |

|

Item 13. |

Certain Relationships and Related Transactions, and Director Independence |

64 |

|

Item 14. |

Principal Accounting Fees and Services |

65 |

|

|

|

|

|

PART IV |

|

65 |

|

Item 15. |

Exhibits, Financial Statement Schedules |

65 |

|

Item 16 |

Form 10-K Summary |

67 |

|

SIGNATURES |

68 |

|

PART I

Unless the context otherwise requires, in this Annual Report on Form 10-K (the “Form 10-K”) where we say “we”, “us”, “our”, the “Company” or “SMTC,” we mean SMTC Corporation and its subsidiaries, as applicable. Where we refer to the “industry,” we mean the electronics manufacturing services industry. Unless otherwise noted or the context otherwise requires, all references to years in this report are to fiscal years.

This Form 10-K and other communications made by us contain forward–looking statements within the meaning of Section 21E of the Securities Exchange Act of 1934, as amended (the “Exchange Act”). The forward-looking statements in this Form 10-K regarding, among other things, our cessation of manufacturing operations in China, the electronics manufacturing services industry, our expectations regarding our future performance, liquidity and capital resources and other non-historical statements include numerous risks and uncertainties, some of which are as described in the “Risk Factors” section in this Form 10-K. Statements using words such as “could”, “expects”, “may”, “anticipates”, “believes”, “intends”, “estimates”, “plans”, “envisions”, “seeks” and other similar language are considered forward looking statements under applicable securities laws. These statements are based on our current expectations, estimates, forecasts and projections about the operating environment, economies and markets in which we operate. These statements are subject to important assumptions, risks and uncertainties, which are difficult to predict and the actual outcome may be materially different. Moreover, we operate in a competitive and rapidly changing environment. New risks emerge from time to time and it is not possible for us to predict all risk factors, nor can we address the impact of all factors on our business. You should not place undue reliance on any forward-looking statement, each of which applies only as of the date of this Form 10-K. Except as required by applicable law, we undertake no intention or obligation to update these forward-looking statements after the date of this Form 10-K, even though our situation may change in the future. All forward-looking statements attributable to us are expressly qualified by these cautionary statements.

|

Item 1. |

Business |

Overview

We are a provider of end-to-end electronics manufacturing services (“EMS”), including product design and engineering services, printed circuit board assembly (“PCBA”), production, enclosure, cable assembly, precision metal fabrication, systems integration and comprehensive testing services, configuration to order (“CTO”), build to order (“BTO”) and direct order fulfillment (“DOF”). At the end of 2019, we operated more than 50 manufacturing and assembly lines in over 555,000 square feet of production space worldwide at strategically located facilities in the United States and Mexico, that provide local support, flexibility, fast turn around and delivery times, and low-cost, volume manufacturing capabilities, as well as new product integration (“NPI”) services, to our global customers. Our services extend over the entire electronic product life cycle from new product development and NPI through to growth, maturity and end of life phases. Our focus on delivering best-in-class services has been recognized and we have received Frost & Sullivan Awards for Product Quality, Growth Leadership & Customer Value Leadership Awards in May 2019.

During the fourth quarter of 2019 we ceased manufacturing in China and began to relocate the equipment used at our Chinese manufacturing facility to our other North American sites. Customer concerns about uncertainties relating to the prolonged impact of tariffs and macro-economic factors caused a number of our customers to begin to re-evaluate demand for some of their products and reconsider where they outsource their manufacturing. Revenues attributable to production from SMTC’s manufacturing operations in China declined in 2019 as compared to 2018, but more significant declines were anticipated in 2020 which would have resulted in negative operating margins from our China site. This ultimately resulted in the decision to close the manufacturing facility.

We offer fully integrated contract manufacturing services to global original equipment manufacturer (“OEMs”), technology companies, Defense Prime Contractors, the U.S. Department of Defense (“DoD”), and various U.S. government agencies. We are focused on seven market sectors:

|

● |

Avionics, aerospace and defense; |

|

● |

Industrial, power and clean technology; |

|

● |

Medical and safety; |

|

● |

Retail and payment systems; |

|

● |

Semiconductors; |

|

● |

Telecom, networking and communications; and |

|

● |

Test and measurement. |

We have customer relationships with industry leading OEMs, Defense Prime Contractors, the DoD, and various other U.S. government agencies. We developed these relationships by capitalizing on the continuing trend of OEMs outsourcing non-core manufacturing services to consolidate their supplier base and forming long-term strategic partnerships with select high-quality EMS providers. We work closely with, and are highly responsive to, our customers throughout the design, manufacturing and distribution process, providing value-added services. We seek to grow our business through the expansion of our share of business with existing customers, participating in the growth of existing customers, the addition of new high-quality customers, and from time-to-time, through strategic acquisitions, such as our acquisition of MC Assembly Holdings, Inc. (“MCA”), a privately held EMS provider based in Melbourne, Florida, in November 2018 (the “MCA Acquisition”). In connection with the MCA Acquisition, we expanded our operations to include locations in Melbourne, Florida, Billerica, Massachusetts, and Zacatecas, Mexico. Our Melbourne, Florida operation provides comprehensive electronic manufacturing services with a focus on delivering product to our customer base in the most cost-efficient manner. Our Billerica, Massachusetts operation has the same competencies as our operation in Florida, but on a smaller scale. An ISO 9001/2008 2015 approved quality system allows for strict controls and process discipline on our manufacturing floor. Our Zacatecas, Mexico operation is a ‘Copy-Exact’ facility of our Melbourne, Florida operation, which functions within the guidelines of ISO-9001:2008 2015 and ISO-13485:2016 Quality System and provides similar manufacturing as our U.S.-based operations with the advantage of the lower cost of labor.

We believe that one of the fundamental benefits we offer is our strategic approach in working with customers. This approach involves gaining insight into their business and bringing innovative solutions to enhance their competitiveness, time to market and profitability. We seek to lower total cost of ownership, improve product quality and reliability, accelerate new products to market, improve service and DOF,, reduce working capital requirements and capital expenditures, all of which results in improvement of our customers’ overall margins and end customer satisfaction.

Industry Background

The EMS sector is the outsourced portion of the worldwide electronics assembly industry. EMS has experienced significant change and growth as an increasing number of companies elect to outsource some or all of their design, manufacturing, and after-market services requirements. There is currently considerable outsourcing of manufacturing by traditional OEMs and more recent market entrants in response to rapidly changing markets, technologies and accelerating product life cycles as well as the need to lower total costs and convert typical fixed costs into a variable cost model.

Historically, OEMs were vertically integrated manufacturers that invested significantly in manufacturing assets and facilities around the world to manufacture, service and distribute their products. EMS originated as labor intensive functions that OEMs outsourced to obtain additional capacity during periods of high demand. Early EMS providers were essentially subcontractors, providing production capacity on a transactional basis. However, with significant advances in manufacturing process technology, EMS providers developed additional capabilities and were able to improve quality and dramatically reduce OEMs’ costs. Furthermore, as the capabilities of EMS companies expanded, an increasing number of OEMs adopted and relied upon EMS outsourcing strategies. Over time, OEMs engaged EMS providers to perform a broader array of manufacturing services, including design and development activities. In recent years, EMS providers have further expanded their range of services to include advanced manufacturing, configuration, packaging and distribution and overall supply chain management. In addition, many OEMs are reducing the number of vendors from which outsourced services are purchased and are partnering with EMS suppliers that offer broader expertise. The EMS industry has also seen an increased level of diversification by many companies, primarily in the technology sector. Companies that have historically identified themselves as software providers, internet service providers, or e-commerce retailers are entering the highly competitive and rapidly evolving mass hardware markets, with products including mobile devices, home entertainment products, and wearable devices.

By outsourcing manufacturing, OEMs can take advantage of the technology and manufacturing expertise of EMS companies and focus on their core business, while leveraging the manufacturing efficiency of and capital investment made by EMS providers. OEMs use EMS providers to enhance their competitive position by:

|

• |

Lowering Product Costs. EMS providers are better able to reduce total product costs due to electronic manufacturing expertise and higher utilization of manufacturing capacity spread over a wider range of product types. Due to their scale of operations as well as their established and ongoing relationships with suppliers, EMS providers are able to achieve better pricing and better working capital management. |

|

• |

Reducing Time to Market. Electronic products are experiencing shorter product life cycles, requiring OEMs to continually reduce the time required to bring new products to market. OEMs can significantly improve product development cycles and reduce time to market by benefiting from the expertise and infrastructure of EMS providers. This expertise includes capabilities relating to design, quick-turn prototype development and rapid ramp-up of new products to high volume production, with the critical support of worldwide supply chain management. |

|

• |

Ability to focus on core branding and R&D initiatives. Through outsourcing, OEMs are able to focus on marketing and product development initiatives which have taken on more prominence as product life cycles have shortened, and as electronic products have become more sophisticated and complex, while at the same time many end markets have become more competitive with companies that have historically identified themselves as software providers, internet service providers, or e-commerce retailers entering the highly competitive and rapidly evolving hardware markets. |

|

|

• |

Improving Supply Chain and Inventory Management. OEMs that manufacture internally are faced with greater complexities in planning, sourcing, procurement and inventory management due to frequent design changes, short product life cycles and product demand fluctuations. OEMs can address these complexities by outsourcing to EMS providers that possess sophisticated supply chain management capabilities and can leverage significant component procurement advantages to lower product costs. |

|

• |

Accessing Advanced Manufacturing Capabilities and Process Technologies. Electronic products and electronic manufacturing technology have become increasingly sophisticated and complex, making it difficult for many OEMs to maintain the necessary technological expertise and focus required to efficiently manufacture products internally. By working closely with EMS providers, OEMs gain access to high-quality manufacturing expertise and capabilities in the areas of advanced process, interconnect and test technologies. |

|

• |

Improving Access to Global Markets. OEMs are generally increasing their international activities in an effort to expand sales through access to foreign markets. EMS companies with worldwide capabilities are able to offer those OEMs global manufacturing solutions enabling them to meet local content requirements and to distribute products efficiently around the world at lower costs. |

|

• |

Reducing Capital Investments. OEMs are able to reduce their capital investments in inventory, facilities and equipment by outsourcing their manufacturing to EMS providers and allocating their resources towards their core business activities. |

|

• |

Shift from a Fixed to Variable Cost Model. Through outsourcing, OEMs are able to shed substantial fixed costs of manufacturing and take advantage of EMS providers’ efficient facilities, resulting in a highly variable and more efficient cost structure. |

Our Capabilities and Performance

Our EMS activities span the entire electronic product life cycle from the development and introduction of new products through the growth, maturity, and end of life phases. We believe that our focus on quality, superior supply chain management and innovative manufacturing services have the capabilities to reduce our customers’ product costs and time to market, which improves our customers’ competitiveness. We continuously work with our customers to identify, prioritize and implement opportunities for cost reduction.

We offer three vertically-integrated manufacturing streams: enclosures and precision metal fabrication products; PCBA products; and larger-scale systems. For each of these streams, we provide a broad range of end-to-end manufacturing services, from assembly, test, integration and box-build through to system level test, CTO, BTO and DOF. These core services are complemented with cable assembly, interconnect and value engineering services. Our three manufacturing streams are vertically integrated to better control quality, lead times and inventory risk and to avoid lost margin that can occur when these services are provided by loosely connected entities. Our customers benefit from lower costs, better quality, and shorter lead times.

Our vertically-integrated manufacturing services include:

New Product Introduction Services. In 2019, we added a new capability to our Billerica, Massachusetts, United States location that provides our customers with world-class 'Quick-turn' manufacturing. This new capability is designed to enable an accelerated launch timetable for our customers’ products with the flexibility to scale into a low-cost geography that is available from other SMTC sites.

PCBA Services. We provide advanced product assembly and system level integration and test services combined with advanced manufacturing equipment and processes. Our flexible environment allows us to support low-medium and high-mix and volume manufacturing requirements as well as to deliver a final product directly to the end customer.

System-Level Integration, Box-Build and Test. Our system and subsystem assembly services involve combining a wide range of subassemblies, including PCBAs, cables and harnesses, battery boxes and connector blocks, power supplies, backplanes and thermal controls. Our test expertise encompasses the full array of technologies present in today’s system level products, including high-speed digital, radio frequency, precision analog, power, thermal and optical. We provide complete electrical and mechanical testing for cables, harnesses, PCBAs, subassemblies and systems to meet our customers’ requirements and specifications. Our in-house expertise enables us to provide custom test development services to our customers and to implement their product specific tests.

Enclosures and Precision Metal Fabrication. We use premium grade sheet steel, stainless steel, and aluminum to ensure high quality. Technologically advanced equipment and processes enable us to produce medium to complex product enclosures and metal parts while still achieving a low overall product cost. Our soft tooling approach minimizes upfront costs and provides flexibility to respond quickly to engineering changes.

Custom Interconnect. We are experienced in the design, development and manufacturing of interconnect assemblies such as optical and electrical cable and harness assemblies offering customers advanced expertise and low-cost options.

Engineering Services. We provide services across the entire product life cycle including product design, prototyping, qualification testing and sustaining engineering through product end of life.

Global Procurement and Supply Chain Network. As an extension of our offering of vertically-integrated manufacturing services, our Global Procurement Group (“GPG”) plays a fundamental role in our managing a portfolio of assets and relationships in the most efficient manner. Our GPG has expertise that includes outsourcing based on market conditions and demand management criteria established with the customer, building flexibility into the supply chain network, designing a supply chain specific to individual customer needs, and having the ability to proactively plan. A key element of our business is to work closely with our customers to anticipate and/or react to changing market conditions, For example, in 2018 we worked with our customers and key partners and implemented a number of initiatives to manage the risks associated with the industry’s then component shortages as well as new tariffs. These initiatives included a new supply chain center in Phoenix, Arizona opened in 2018, the expanded use of lean manufacturing kan-ban programs, upgraded quoting-tools, tailor-made customer-specific action plans, new agreements with Tier-1 distributors, and extensive investments in safety stock programs. Our GPG is responsible for all aspects of our supply network. Our GPG, led by personnel that have gained experience with large organizations where they have developed key relationships, works together with our customers to establish customized inventory, logistics and distribution services to ensure that any unique delivery requirements are met. Through the use of various management tools, our supply chain team focuses on driving improved inventory turns, lowering excess and obsolete inventory risk and reducing overall costs to our customers.

Management Methods and Tools. We have a web-based system through which it can communicate, collaborate and plan throughout the entire supply chain in real-time with our customers and suppliers. This system accelerates the timeliness and effectiveness of decision making and the efficiency and flexibility with which we can plan for and respond to customers experiencing market fluctuations. We employ technologically advanced quality assurance systems, manufacturing process planning and continuous improvement methodologies.

Our Footprint

At the end of 2019, we operated more than 50 manufacturing and assembly lines in over 555,000 square feet of production space worldwide at strategically located facilities in the United States, and Mexico,, that provide local support, flexibility, fast turn around and delivery times, and low-cost, volume manufacturing capabilities, as well as NPI services, to our global customers. During the fourth quarter of 2019 we ceased manufacturing in China and began to relocate the equipment used at our Chinese manufacturing facility to our other North American sites.

All our manufacturing facilities adhere to the “Copy Exact” methodology. Our “Copy Exact” process enables a seamless and timely transition of production between facilities to help customers reach their cost and volume targets faster. We also assign a dedicated manufacturing unit to each customer.

Key Benefits to Our Customers

Three overarching themes form the core of our differentiation and unique customer value proposition: trusted, proven, and professional. These three themes are exemplified by the following aspects of our business:

Operational Counterpart: Fundamental to our strategic approach in working with customers is to take the time to understand our customers’ business objectives, end markets, performance expectations, competitive advantage, positioning and strategy—to drive better value. We get involved with our customers at both a strategic and operational level. As a trusted partner, we seek to become an extension of their business, helping our customers grow, improve competitiveness, margins, and gain market share.

The Customer Experience: We combine strong performance with a partnership approach that delivers tangible, bottom-line benefits through committing expertise and resources towards customer goals. We believe it is one of many reasons that a number of our customers have been with us for many years.

People: Our customer-based teams are tied to the customer at a strategic, operational and organizational level. Our people create an environment that celebrates collaboration and teamwork. We foster a participatory workplace that enables people, at every level of the organization, to get involved in making decisions that put the customer first.

Executive Mindshare: We fully engage with our customers on many levels—from operational and executive mindshare, to custom-tailored solutions as part of strategic partnership approach to doing business. Our senior management, each of whom has strong relationships with customers from their previous positions at larger companies, are armed with real-time operational metrics and quality data, and are accessible to and actively involved with our customers.

Strategic Fit: Fit matters. Winning OEMs look for winning manufacturing partners. We mitigate the risk of outsourcing and seeks to deliver results and value.

Global Footprint: At the end of 2019, we operated more than 50 manufacturing and assembly lines in over 555,000 square feet of production space worldwide at strategically located facilities in the United States, and Mexico, that provide local support, flexibility, fast turn around and delivery times, and low-cost, volume manufacturing capabilities, as well as NPI services, to our global customers. During the fourth quarter of 2019 we announced a decision to cease manufacturing in China and relocate the equipment used at our Chinese manufacturing facility to our other North American sites.

Supply Chain Expertise: We deliver supply chain capabilities and solutions that support the total product life cycle. Our extended supply chain model recognizes the need for collaboration between our customers, our Company and our supply partners to ensure overall supply chain optimization, from product design processes, manufacturing, sourcing, order management and fulfillment to transportation and logistics. The end result is greater control over a complex, extended supply chain to help our customers realize flexibility, cost savings, process improvements, and competitive advantages.

Superior Value: We continuously work collaboratively with customers to identify, prioritize and implement opportunities for cost reduction. Working collaboratively helps ensure superior service, operational excellence and continuous cost improvement.

Customized Solutions: By gaining insight into our customers businesses, we can proactively tailor customized solutions to their unique challenges to enhance their competitiveness, time to market and profitability.

Our Corporate Objective and Strategies

Our corporate objective is to create sustainable growth and increase stockholder value through growth in sales, profitability and debt minimization. A cornerstone to our business is our customer-centric focus throughout the organization.

Our key strategies include:

Provide Outstanding Customer Service and Performance. Customer acquisition and loyalty comes from our ongoing commitment to understanding our customers’ business performance requirements and our expertise in meeting or exceeding these requirements and enhancing their competitive edge. Our customer focus extends to our unique offering of dedicated resources, a detailed understanding of our customers’ challenges and means to support our customers in meeting their goals. Our dedicated team approach is used throughout our Company and comprises members from all functional areas working together to better understand the unique needs of each customer, their challenges and their future plans. Our commitment to understanding each customer’s goals, challenges, strategies, operations and products to provide a better overall solution is a key focus for our operations personnel and our senior executive team.

Focus on Well Defined Customer Markets. We focus on specific customer sectors (and within those sectors target a wide range of projects that offer higher value add) that align well with our capabilities:

|

● |

Avionics, aerospace and defense; |

|

● |

Industrial, power and clean technology; |

|

● |

Medical and safety; |

|

● |

Retail and payment systems; |

|

● |

Semiconductors; |

|

● |

Telecom, networking and communications; and |

|

● |

Test and measurement. |

Customers with unique medium to high-mix and volume production requirements with a need for a high level of responsiveness to changing market demands are particularly well suited for our capabilities. We continue to leverage our experience and established relationships in our existing market segments. Through the MCA acquisition, we have increased and expect to continue to expand our business in the avionics, aerospace and defense markets and have been able to further penetrate into the medical and safety market sectors. We target a wide range of projects in the sub-$5 million range that offer higher value add than larger projects typically targeted by Tier-1 EMS competitors.

Provide Advanced Technological Capabilities. We remain committed to enhancing our capabilities and value-added services to become an integral part of our customers’ operations. Through our investment in assembly and fabrication technologies and in design, engineering and test capabilities, we are able to provide our customers with a variety of advanced design and manufacturing solutions.

Provide Comprehensive Service Offerings. Our broad array of EMS activities span the entire electronic product life cycle from introduction and development of new products to the support of products to growth and maturity phases. We perform advanced PCBA and test and complement these capabilities with precision enclosure fabrication, system integration, product configuration, and BTO services. As products mature, we provide comprehensive value engineering services to reduce the cost of the products we produce without compromising quality or function. As products near their end of life, our sustaining engineering and supply chain management systems ensure continued availability and support of hard to source components while mitigating the risks associated with declining inventories. We believe that our breadth of services provides greater control over quality, delivery and costs and enables us to offer our customers a complete, end-to-end solution that is time and cost effective.

Maintain a Competitive, Scalable Cost Structure. We maintain a competitive cost structure that not only delivers highly competitive pricing to customers but is also both variable and scalable as market conditions dictate. We strive to improve profitability through tight cost containment measures, performance excellence, leveraging fixed costs and increased capacity utilization. The MCA Acquisition has enabled us to become a more efficient operator, including sourcing cost reductions, the elimination of certain redundancies in our corporate and shared services, and an increase in manufacturing capacity to better serve existing and new customers. The MCA Acquisition has also accelerated our entry into several new complex and highly regulated, attractive markets that present the opportunity for higher margins, including our entry into the avionics, aerospace and defense markets, and further allowed us to further penetrate into medical industries which we had targeted and previously received key industry certifications.

Technology, Processes and Development

Our engineering services team delivers a wide range of design, engineering and manufacturing solutions. We have electronic engineering expertise in our targeted customer markets. We maintain manufacturing equipment and tools to the highest calibration standards possible. We follow a comprehensive preventative maintenance program. Customers rely on our full range of design services—from software and firmware development, to electronic design, mechanical design and PCB layout. Our design services capability optimizes product design for maximum performance, higher yields, and faster time to market, with the objective of assisting our customers in becoming more profitable and more competitive. We partner with our customers to deliver innovative manufacturing solutions aligned with their business objectives. We offer everything from full-service, turnkey product development and manufacturing to on-site engineering support.

Our box build experience spans the past 20 years with all manufacturing sites supporting current customers in this level of outsourcing. Our integration and box build assembly services combine a wide range of subassemblies, including PCBAs, cables and harnesses, external housing (plastic and metal), monitors, battery boxes and connector blocks, power supplies, fan trays, backplanes and thermal controls. Integrated units are packaged, together with manuals, software, and peripherals. DOF and BTO are handled throughout the integration service, specific to the needs of our customers.

Our DOF and distribution operations help our customers reduce material storage, lower handling costs and achieve higher inventory turns. We also provide responsive, efficient and cost-effective configure to order and order fulfillment solutions. We align our processes with the customers’ operations, sales and distribution objectives to eliminate redundancies and associated costs.

We continue to invest in new processes and equipment that enable the assembly of industry leading product designs. In 2019, we invested approximately $4 million primarily related to equipment expansion in North America to support our growing global customer base.

We believe that we apply best-in-class quality programs, processes and metrics to achieve exceptional quality standards. We endeavor to fully understand the quality requirements for every customer and we continuously review to improve our quality performance to exceed customer expectations. All of our sites currently use Computer Integrated Manufacturing (“CIM”), a common quality management platform. The CIM system tracks quality assurance processes in real-time and reports on all steps in the manufacturing process. We are continuing to make investments in quality, and are in the process of replacing the existing CIM system with Factory Logix, a product from Aegis Industrial Software. This investment will improve transaction control on the production floor and traceability at the component and product level. We use a customer-centric, team-based approach to quality assurance. Dedicated professionals work with our customers to determine key quality requirements, and where applicable, they ensure suppliers adhere to those standards as well. All of our sites are certified with the International Organization for Standardization (“ISO”) ISO-9001 quality management system standard and ISO-13485 medical standards. All ISO 9001 registrations are to the latest level (2015 version of the standard). All of our sites have also achieved the Environmental Management Standards ISO-14001 certification. We build PCBAs according to IPC standards, an association connecting the electronic industries, and has been an IPC member since 1991. We also work closely with standards organizations such as Underwriters Laboratories, a safety consulting and certification company and Canadian Standards Association, in compliance with customer requirements. Our Fremont, California and Chihuahua, Mexico locations are registered FDA facilities and are in compliance with federal Good Manufacturing Practice and the Quality System Regulations. To support our diverse customer base which includes customers in several highly regulated industries, we have achieved a number of required industry certifications, compliance requirements and governmental registrations, including Apple® Authorized Mfi Manufacturing License 6.0, AS9100, Cage Code: 4X3Y1, cGMP Compliant, FAA: PMA Certified, FDA Registration, IATF 16949, IPC-610 Class 3, ISO 9001, ISO 14001, ISO 13485, ITAR Registration, J-STD -001, and TRAC: 4144-7785-7736.

We achieved AS9100 accreditation at our Billerica, Massachusetts, Fremont, California and Melbourne, Florida facilities. We have also achieved ISO-13485 certification at all sites worldwide. ISO-13485 is an internationally recognized quality management system and standard for the manufacture of medical devices. Our Fremont, California and Chihuahua, Mexico locations are registered FDA facilities and are in compliance with federal Good Manufacturing Practice and the Quality System Regulations.

Marketing and Sales

Our direct sales channel model is organized and managed with territorial assignments based on geographical coverage of our target markets globally. We have developed relationships and established a network of sales representatives that focus on specific territories in the U.S. The MCA acquisition in 2018 further expanded our network of marketing representatives and agencies. Our marketing and sales team work collaboratively to gain insight on potential customers’ business and market positioning and focus on a solutions-based approach to enhance profitability, market positioning and business performance for customers.

We develop relationships with our customers and market our vertically-integrated manufacturing services through our direct marketing and sales teams. Our direct sales teams work closely with the customers' engineering and technical personnel to better understand their requirements. Our marketing team supports our business strategy of providing end-to-end services by encouraging cross selling of vertically-integrated manufacturing services across a broad range of major OEM products. To achieve this objective, our marketing and sales teams work closely with our various manufacturing, design and engineering groups to engage in marketing and sales activities targeted towards key customer opportunities.

Our customer-centric focus continues through to the execution phase of our relationships with a dedicated customer focused team-based manufacturing approach throughout all of our facilities. A dedicated account team including a global account manager are directly responsible for managing each of our key customer accounts. Global account managers coordinate activities across geographic locations to effectively satisfy customer requirements and have direct access to our senior management to quickly address customer concerns. Local customer account teams further support the global teams and are linked by a comprehensive communications and information management infrastructure.

Our largest customer and 10 largest customers represented 12.8% and 52.8%, 10.9% and 68.1%, and 11.9% and 72.5%, respectively, of our total revenue for the fiscal years ended December 29, 2019, December 30, 2018 and December 31, 2017. We expect to continue to depend upon a relatively small number of customers for a significant percentage of our revenue. In addition to having a relatively limited number of customers, we manufacture a relatively limited number of products for each of our customers. See “Item 1A. Risk Factors—Risks Related to our Business and Strategy—A majority of our revenue comes from a relatively small number of customers. If we lose any of these customers, our revenue could decline significantly.”

Global Procurement and Supply Chain Management

We deliver supply chain capabilities and solutions that support the total product life cycle. Our teams work closely with customers’ supply-base partners to integrate the entire supply chain. Our extended supply chain model recognizes the need for collaboration between OEM customers, our Company and supply partners to ensure overall supply chain optimization, from product design processes, manufacturing, sourcing, order management and fulfillment to transportation and logistics. The end result is greater control over a complex, extended supply chain to help our customers realize flexibility, cost savings, process improvements, and competitive advantages.

In lean manufacturing environments, success is defined by how fast and how effectively manufacturers can respond to evolving customer demands and new global supply chain conditions. We leverage supply chain tools and systems to respond rapidly and effectively to changing real-world conditions. Our customers rely on our core processes and capabilities to drive the success of their supply chains. Each supply chain solution we deliver is tailored to address each customer’s unique requirements.

We employ Agile Product Lifecycle Management (“Agile”) solutions software to help OEMs accelerate revenue, reduce costs, improve quality, ensure compliance, and drive innovation throughout the product life cycle. Agile provides comprehensive support for product life cycle business processes, platform and integration requirements. Agile enables a single enterprise view of the product and part records across the entire system, helping customers accelerate new product introduction time, reduce direct material costs and ensure regulatory compliance.

The demand management process is a core process at our Company, which drives short- and long-term planning and execution activities. Effective demand management optimizes materials availability, supply-base performance and overall liability management. We recognize the need to deploy people, process and technology, as well as extensive customer communication and visibility, to ensure effective demand management execution. This allows for real-time analysis, feedback and implementation of changes in customer and end-market demand, rapid communication to suppliers of changes in requirements, and a truly responsive end-to-end supply chain.

We also employ Kinaxis RapidResponse, an integrated response management tool that allows supply chain professionals to access real-time information and enable collaboration across extended supply networks. The tool allows us to perform real-time demand scenario simulation, review supply constraints, perform rapid manufacturing resource planning, clear to build analysis and communicate changes in requirements to suppliers—all on the same day. With Kinaxis RapidResponse, our teams are able to achieve high levels of supply chain agility with immediate response to changes in demand, supply, capacity and daily operations. The platform enables real-time supply chain visibility and on-line collaboration anywhere in the world. In this way, we gain the insight needed to quickly and effectively respond to a wide variety of supply chain challenges.

Visibility solutions are customized to support a range of requirements, including inventory visibility, master production schedule simulation, clear-to-build, available-to-promise, end-market demand steering, and service parts management. Kinaxis RapidResponse provides a single view of inventory across all of our facilities as well as a view of materials supply. Custom reports can be automatically emailed within our Company and to our customers on regular intervals. This inventory and supply base liabilities dashboard has proven to be a valuable tool for both our Company and our customers. Visibility solutions include intercompany processes and multi-node supply chains.

We have a global commodity manager in Kowloon, Hong Kong who serves to improve access to the broad base of component suppliers in the Asia region and provides us with competitive pricing. The Hong Kong office manages component sourcing to support our global operations. During 2018, a supply chain center was opened in Phoenix, Arizona. The Phoenix, Arizona location serves as an office for supply chain staff and other members of management. During the fourth quarter of 2019, various news reports have been published on the new Coronavirus, originating within China and considerations of the impact on the economy or more specifically those companies relying on China for supply chain and or having facilities located there. SMTC’s supply chain and its executive team are actively monitoring the Coronavirus and taking actions to mitigate the financial impact on the Company. This included identifying the key components sourced from China required for first quarter and second quarter 2020 demand and confirming commitments from suppliers of those components and changing lead times accordingly. Please see Our supply chain in China may be materially adversely impacted due to the recent coronavirus outbreak outlined in the risk factors under Item1A below.

Our Suppliers

Kinaxis RapidResponse works hand-in-hand with custom electronical data interchange (“EDI”), business-to-business process that provides real-time and daily information exchange and transactions with suppliers. Through EDI programs, we have an ongoing view into supplier on-hand inventories and are able to more effectively plan factory capacities and provide customer delivery commitments.

With our web-based collaborative planning systems, our customers’ needs are integrated with our suppliers in a more efficient and cost-effective manner than is achievable through traditional EDI. We believe our volume of procurement enhances our ability to obtain better pricing, influence component packaging and design and obtain supply of components in constrained markets.

We generally order materials and components under our agreements with customers only to the extent necessary to satisfy existing customer orders or forecasts. We have implemented specific inventory management strategies with certain suppliers via vendor managed inventory programs into our supply chain programs. Fluctuations in material costs typically are passed through to customers. We may agree, upon request from our customers, to temporarily delay shipments, which causes a corresponding delay in our shipments and an increase in inventory, which impacts our working capital management. Ultimately, however, our customers generally are responsible for all materials purchased and goods manufactured on their behalf.

Our Customers

We are a distinctive mid-tier EMS provider, supporting customers in the following market sectors:

|

● |

Avionics, aerospace and defense; |

|

● |

Industrial, power and clean technology; |

|

● |

Medical and safety; |

|

● |

Retail and payment systems; |

|

● |

Semiconductors; |

|

● |

Telecom, networking and communications; and |

|

● |

Test and measurement. |

Revenue in 2019 was attributed to the following industry sectors: 31.8% from test and measurement, 20.8% from industrial, power and clean technology, 12.4% from retail and payment systems, 12.2% from medical and safety, 10.0% from telecom, networking and communications, , 6.6% from avionics, aerospace and defense, and 6.2% from semiconductors.

Our Competition

The EMS industry is composed of numerous companies that provide a range of manufacturing services for OEMs, including PCBA, to design, prototyping, final system assembly, configuration, order fulfillment, repair and aftermarket services. The EMS market consists of contract manufacturers (“CMs”), and original design manufacturers (“ODMs”). CMs manufacture products that have been designed by the OEM; ODMs may also design their own products, primarily commodities, and in many instances are in direct competition with the OEMs. We participate in the mid-sized CM sector.

CM providers fall within one of four tiers:

Large/Tier 1: Global operations with manufacturing facilities in North America, Europe and Asia, and low-cost manufacturing sites in Asia, Mexico and Eastern Europe. Large CMs annual revenues generally are greater than $2.0 billion. This includes Celestica Inc., Flextronics International Ltd., Jabil Circuit, Inc., Sanmina, Inc., Benchmark Electronics Inc. and Plexus Corp.

Mid-size/Tier 2: Usually focused in one region such as North America, Europe or Asia, with facilities in that region supported by additional facilities in low-cost regions. Mid-sized CMs generally have annual revenues of up to $2.0 billion. This includes Key Tronic Corp.

Regional /Tier 3: Usually focused in North America and typically with minimum operations in low-cost geographic regions and less than $300 million in annual revenues. This includes IEC and Sigmatron.

Small/Tier 4: Usually single facility operations, with annual revenues less than $20 million.

We compete with different companies depending on the type of service we are providing and/or the geographic area in which an activity takes place. Some of our competitors may have greater scale and provide a broader range of services than we offer. We believe that the principal competitive factors in the manufacturing services market are quality and range of services, design and technological capabilities, cost, location of facilities, responsiveness and flexibility. To remain competitive, we believe we must continue to provide technologically advanced manufacturing services and solutions, maintain quality levels, offer flexible delivery schedules, deliver finished products and services on time and compete favorably on price.

Environmental and Social Commitment

Our commitment is to conduct our business in such a way that protects and preserves the environment, health and safety of our employees, our customers and the communities where we live and operate. Our commitment to this responsibility includes compliance to the European Directives: Waste Electronic and Electrical Equipment, Restriction of Hazardous Substances, as well as assisting customers with conflict minerals and complying with the human trafficking resolutions passed in the California Transparency in Supply Chains Act of 2010. Our commitment goes beyond merely compliance. For example, our MCA Acquisition reduced its annual water consumption by more than 74 percent by investing in the implementation of a Closed Loop Process Water Recycling System at our Melbourne manufacturing facility.

Our Structure and Our History

We were established in Toronto, Canada in 1985. We are a Delaware Corporation incorporated in July 1998. Our present corporate structure resulted from the July 1999 combination of predecessor companies Surface Mount Technology Centre Inc., an Ontario, Canada corporation (“Surface Mount”) and HTM Holdings Inc., a Delaware corporation (“HTM”). Subsequent to the combination, all of Surface Mount’s operating subsidiaries, other than SMTC Canada and Qualtron, Inc., became subsidiaries of HTM. In 2011, we expanded our operations in San Jose, California with the acquisition of ZF Array Technology, Inc. , a privately held electronics manufacturing services provider. In 2012, the Asian entities of SMTC Electronics Dongguan Company Limited and SMTC Electronics (Suzhou) Company Limited were established. Our SMTC Electronics (Suzhou) Company Limited, China facility was closed in accordance with the restructuring plan as announced on May 15, 2017. The closure of the SMTC Electronics (Suzhou) Company Limited, China facility was substantially completed by the end of 2017. In November 2018 we also acquired MCA, a privately held electronics manufacturing services provider. During the fourth quarter of 2019 we announced a decision to cease manufacturing at SMTC Electronics Dongguan Company Limited and relocate the equipment used at our Chinese manufacturing facility to our other North American sites. The closure of the SMTC Electronics Dongguan Company Limited, China facility is expected to be substantially completed by the end of the first quarter of 2020.

Our Leadership Team

In May 2017 Ed Smith was appointed as our Company’s President and Chief Executive Officer. Mr. Smith’s EMS career spans over three decades and has served as President of AVNET Inc., a multibillion-dollar electronic components distributor, and as President and Chief Executive Officer at SMTEK International Inc., a Tier III EMS manufacture. Following Mr. Smith’s appointment, we added several experienced leaders to our senior management team with strong industry backgrounds, including previous success in building businesses together as a team.

Order Backlog

Our order backlog is typically a combination of purchase orders and forecasts. Our customers typically provide purchase orders for delivery of products due within 30 to 90 days. We are also provided additional demand beyond 90 days to drive material demand and perform resources and capacity planning. Furthermore, backlog as of a particular date is affected by a number of other factors, including manufacturing schedules and the timing of product shipments. Backlog also is affected by the timing of customers’ orders and product availability. Due to these factors and business model differences around the globe and since additional orders may be added, or orders rescheduled or cancelled, we do not believe that the order backlog of expected product sales covered only by purchase orders is a meaningful measure of future sales and we believe backlog is an imprecise indicator of future revenues that may be achieved in a fiscal period and cannot be relied upon.

Employees

As of December 29, 2019, we had 2,805 employees of which 2,546 were full time and contract employees. In addition, we employ varying levels of temporary employees as our production demands. Given the variable nature of our project flow and the quick response time required by our customers, it is critical that we are able to quickly adjust our production levels to maximize efficiency. To achieve this, our strategy has been to employ a skilled temporary labor force, as required. We use outside contractors to qualify our temporary employees on a site-by-site basis. Our production level temporary employees are compensated by the hour. We believe we are team-oriented, dynamic and results-oriented with an emphasis on customer service and quality at all levels. We believe this environment is a critical factor for us to be able to fully utilize the intellectual capital of our employees. Because of the surplus of available talent on the market, and the strength of our total compensation packages, to date we have not experienced any issues attracting skilled employees.

As of December 29, 2019, our only unionized employees were at our Chihuahua, Mexico facility, representing approximately 37% of our Mexican labor force. We have never experienced a work stoppage or strike and believe we have good employee relations.

Additional Information

We are subject to the reporting requirements under the Exchange Act. Consequently, we are required to file reports and information with the Securities and Exchange Commission (the “SEC”), including reports on the following forms: Annual Reports on Form 10-K, Quarterly Reports on Form 10-Q, Current Reports on Form 8-K, and amendments to those reports filed or furnished pursuant to Section 13(a) or 15(d) of the Exchange Act. These reports and other information concerning us may be accessed, free of charge, through the SEC’s website at www.sec.gov and on our corporate website address at www.smtc.com. We make such filings available through our corporate website as soon as reasonably practicable after we electronically file such material with, or furnish it to, the SEC. Reference to our website is for informational purposes only and the information contained in, or that can be accessed through, our website is not incorporated by reference into this Form 10-K.

|

Item 1A. |

Risk Factors |

RISKS RELATED TO OUR BUSINESS AND INDUSTRY

A majority of our revenue comes from a relatively small number of customers. If we lose any of these customers, our revenue could decline significantly.

We operate in a highly competitive and dynamic marketplace in which current and prospective customers often seek to lower their costs through a competitive bidding process among EMS providers. This creates an opportunity to increase revenue to the extent we are successful in the bidding process, but there is also the potential for revenue to significantly decline to the extent we are unsuccessful in the competitive bidding process. Furthermore, even if we are successful, there is the potential for our margins to decrease if we are required to lower our prices in order to win such bids.

Our largest customer and 10 largest customers represented 12.8% and 52.8%, 10.9% and 68.1%, and 11.9% and 72.5%, respectively, of our total revenue for the fiscal years ended December 29, 2019, December 30, 2018 and December 31, 2017. We expect to continue to depend upon a relatively small number of customers for a significant percentage of our revenue. In addition to having a relatively limited number of customers, we manufacture a relatively limited number of products for each of our customers. If we lose any of our largest customers (as we have in the past from time to time), experience a significant reduction in sales to any such customers or no longer manufacture a particular product line for one of our largest customers, we would experience a significant reduction in our revenue. Further, we make no assurance that our largest customers will continue to have us manufacture their products from us at current or historical levels. Moreover, we typically do not enter into long-term volume purchase contracts with our customers, and our customers have certain rights to extend or delay the shipment of their orders. We, however, typically require that our customers contractually agree to buy back inventory purchased within specified lead times to build their products if not used. See also “Our customers may cancel their orders, change production quantities or locations, or delay production, and the inherent difficulties involved in responding to these demands could harm our business.” In addition, because of the concentration in our customer base, we have significant amounts of trade accounts receivable from some of our customers and the insolvency of one or more of our largest customers or the inability of one or more of our largest customers to pay for its orders would decrease our revenue significantly. A reduction in revenue could decrease our profitability, cash flow and adversely affect our business, financial condition and results of operations.

Furthermore, the success of our business depends, in part, on the continued growth and financial stability of our customers, including, in particular, our largest customers. Adverse changes in the end markets these customers serve could reduce demand from our customers in those markets and/or cause customers in such end markets to be more price sensitive, which could cause us to lose sales or require us to lower prices and thereby suffer a decrease in our margins. Further, mergers, acquisitions, restructuring or other consolidations among our customers, or their end customers, could intensify our customer concentration or reduce total demand as the combined entities reevaluate their business and consolidate their suppliers, which could materially and adversely affect our business. In the event of consolidation among our customers, depending on which of the entities involved in the consolidation controls the combined company’s supply chain function following the consolidation, we may not be retained as a preferred or approved manufacturer. In addition, product duplication could result in the termination of a product line that we currently manufacture. While there is also the potential to increase our sales to the combined customer, our revenues could decrease if we are not retained as a continuing supplier. Even if we are retained as a supplier, we may face the risk of increased pricing pressure from the combined customer because of its increased market share and purchasing power.

As a manufacturer, we are particularly exposed to general economic conditions, which could have an adverse impact on our business, operating results and financial condition.

As a result of unfavorable economic conditions, reduced capital spending and changes in our customers’ manufacturing requirements, our revenues could experience significant declines in the future. If general economic conditions deteriorate, including the onset of a global economic recession, other uncertainty in the global economy such as unstable global financial and credit markets or increased inflation and tariffs, we may experience an adverse impact on our business, operating results and financial condition, since end customer demand for our customers’ products could be adversely affected. Due to the current uncertainty surrounding the economy and our ability to predict the effect such conditions will have on its customers, we cannot predict the scope or magnitude of the negative effect that any economic slowdown may have on our business. Further, economic and financial market conditions that adversely affect our customers may cause them to terminate or delay existing purchase orders or to reduce the volume of products they purchase from us in the future. We may have significant accounts receivable outstanding from customers, including our largest customers, that operate in cyclical industries and under leveraged conditions, which could impair their ability to pay amounts owed to us on a timely basis. Our failure to collect a significant portion of those receivables could have a material adverse effect on our results of operations and financial condition. See “—A majority of our revenue comes from a relatively small number of customers. If we lose any of these customers, our revenue could decline significantly.”

Similarly, adverse changes in credit terms extended to us by our suppliers, such as shortening the required payment period for outstanding accounts payable or reducing the maximum amount of trade credit extended to us, could negatively and significantly affect our liquidity and thereby have a material adverse effect on our results of operations and financial condition.

If we are unable to successfully anticipate changing economic and financial market conditions, we may be unable to effectively plan for, and respond to, those changes, which could have a material adverse effect on our business, operating results and financial condition.

Our supply chain in China may be materially adversely impacted due to the recent coronavirus outbreak.

In December 2019, a novel strain of coronavirus began to impact the population of Wuhan, China. We rely upon the facilities of our suppliers in China to support our business as well as to export components throughout the world. As of December 29, 2019, we sourced components from approximately 137 suppliers located throughout China and approximately 40% of the components in our global supply chain were sourced from our suppliers in China during the year ended December 29, 2019. The outbreak has resulted in significant governmental measures being implemented to control the spread of the virus, including, among others, restrictions on manufacturing and the movement of employees in many regions of the country. As a result of the coronavirus and the measures designed to contain the spread of the virus, our suppliers may not have the materials, capacity, or capability to supply our components according to our schedule and specifications. Any reduction in production capacity or supply capacity at factories in China may reduce or even halt the supply of finished goods and necessary components for many of our customers’ products, which could result in product shortages and an increase in our inventory of unfinished products. Further, there may be logistics issues, including our ability and our supply chain’s ability to quickly ramp up production, and transportation demands that may cause further delays. If our suppliers’ operations are curtailed, we may need to seek alternate sources of supply, which may be more expensive. Alternate sources may not be available or may result in delays in shipments to us from our supply chain and subsequently to our customers, each of which would affect our results of operations. While the disruptions and restrictions on the ability to travel, quarantines, and temporary closures of the facilities of our suppliers, as well as general limitations on movement in the region are expected to be temporary, the duration of the production and supply chain disruption, and related financial impact, cannot be estimated at this time. Should the production and distribution closures continue for an extended period of time, the impact on our supply chain in China and globally could have a material adverse effect on our results of operations and cash flows. See “-We depend on a limited number of suppliers for components that are critical to our manufacturing processes and shortages or price fluctuations of component parts specified by our customers could delay product shipment and affect our profitability.” The coronavirus outbreak could also delay our release or delivery of our or our customers’ new or product offerings or require us or our customers to make unexpected changes to such offerings, which may materially adversely affect our business and operating results. Our operating results could also continue to be adversely affected to the extent that the coronavirus outbreak harms the Chinese economy in general. In addition, the coronavirus outbreak could evolve into a worldwide health crisis that could adversely affect the economies and financial markets of many countries, resulting in an economic downturn that could affect demand for our products and our customers’ products and materially adversely affect our business, operating results, and financial condition.

We are exposed to fluctuations in currencies against the U.S. dollar, which could have a material adverse effect on our business and financial results.

As a global company, we have significant costs, primarily payroll denominated in currencies other than the U.S. dollar. Most of our sales and component purchases are denominated in U.S. dollars. Our Canadian, Mexican and Asian payroll, Euro based component purchases and other various expenses are denominated in local currencies. A decrease in the value of foreign currencies relative to the U.S. dollar could result in lower revenues, product price pressures, and increased losses from currency exchange rates. As a result, we may enter into forward foreign exchange contracts to reduce our exposure to foreign exchange currency rate fluctuations related to the forecasted Canadian dollar and Mexican peso. We have decided at this time not to hedge exposure due to foreign exchange currency related to EURO components purchases or Asian payroll. To the extent we are not able to effectively manage this exposure to foreign exchange rate fluctuations, our revenues and profitability could be adversely affected.

Our industry is very competitive and we may not be successful if we fail to compete effectively.

The EMS industry is highly competitive. We compete against numerous large domestic and foreign EMS providers but consider our peer group and direct competitors to be IEC Electronics Corp., Key Tronic Corp., Nortech Systems Inc., Sigmatron International Inc., and Sypris Solutions Inc. We may in the future encounter competition from additional large electronics manufacturers that are selling, or may begin to sell, electronics manufacturing services. Some of our competitors have substantially greater manufacturing, financial, research and development and marketing resources and lower cost structures than us. We also face competition from the manufacturing operations of current and potential customers, which are continually evaluating the merits of manufacturing products internally compared to the advantages of using external manufacturers such as us.

Furthermore, larger EMS providers who have greater direct buying power from component suppliers, distributors and raw material suppliers or who have lower cost structures as a result of their geographic location may operate more efficiently than us. As a result, other EMS providers with significant purchasing and marketing power may have a competitive advantage over us. Our manufacturing processes are generally not subject to meaningful proprietary protection, and companies with greater resources, financial or otherwise, or a greater market presence may enter our market or increase their competition with us. As a result, our competitors could copy our non-proprietary designs and processes after we have invested in development of products for customers, which could allow those competitors to offer customers lower prices on such products. We also expect that our competitors will continue to improve the performance of their current products or services, to reduce the prices of their products or services and to introduce new products or services that may offer greater performance and lower prices. Any of the foregoing could cause our sales to decline, a decrease in our profit margin or a loss of market share.

In addition, increased pressure to limit U.S. defense spending and changes in the U.S. government procurement environment may limit certain future market opportunities for us. For example, the U.S. Department of Defense (the “DoD”) increasingly is committed to awarding contracts through competitive bidding and relying on competitive contract award types. See “—Our financial results depend, in part, on our ability to perform on our U.S. government contracts, and changes in government defense spending and priorities could have consequences on our financial position, results of operations and business.”

If we are unable to continue to compete successfully against our current or future competitors in our core markets, we may experience declines in revenues and market share which could negatively impact our results of operations, financial condition or liquidity.

We experience variability in our operating results, which could increase the volatility of the price of our common stock.

Our annual and quarterly results have fluctuated in the past. The reasons for these fluctuations may similarly impact our business in the future. You should not rely solely on our results of operations in any past period to indicate what our results will be for any future period. Our operating results may fluctuate in the future as a result of many factors, including, but not limited to:

|

• |

variations in the timing and volume of customer orders relative to our manufacturing capacity; |

|

|

• |

introduction and market acceptance of our customers’ new products; |

|

|

• |

changes in demand or market acceptance for our customers’ existing or new products; |

|

|

• |

the accuracy of our customers’ forecasts of future production requirements; |

|

|

• |

changes in customers and customer or product attrition; |

|

|

• |

effectiveness in managing our manufacturing processes, inventory levels and costs; |

|

|

• |

our level of experience in manufacturing a particular product; |

|

|

• |

changes in competitive and economic conditions generally or in our customers’ end markets; |

|

|

• |

price competition; |

|

|

• |

natural disasters that may impede our operations, the operation of our customers’ business, or availability of manufacturing inputs from our suppliers; |

|

|

• |

failure or external breach of our information technology systems; |

|

|

• |

willingness of suppliers to supply the Company on normal credit terms; and |

|

|

• |

changes in the cost, or availability, of components or skilled labor. |

In addition, most of our customers typically do not commit to firm production schedules more than 30 to 90 days in advance. Accordingly, it is difficult for us to forecast the level of customer orders with certainty. As a result, we may not be able to schedule production to maximize utilization of our manufacturing capacity. In the past, we have been required to increase staffing, purchase materials and incur other expenses to meet the demand of our customers. Sometimes anticipated orders from customers have failed to materialize and, at times, delivery schedules have been deferred as a result of changes in a customer’s needs. Any material delay, cancellation or reduction of orders from our larger customers could cause our revenue to decline. In addition, a reduction in customer demand may decrease our gross margins and adversely affect our business, financial condition and results of operations. On other occasions, customers have required rapid and unexpected increases in production, which have placed burdens on our manufacturing capacity and supply chain function and adversely affected costs. See “—If we are unable to maintain satisfactory utilization rates at our manufacturing factories, our results of operations and financial condition would be adversely affected.”

The EMS industry is affected by the United States and global economies, both of which are influenced by world events. An economic slowdown, particularly in the industries we serve, may result in our customers reducing their forecasts or delaying orders. The demand for our services could weaken, which in turn could substantially influence our sales, capacity utilization, margins and financial results. Results for any one quarter or year are not necessarily indicative of results to be expected for any other quarter or for any year. This could lead to results outside of analyst and investor expectations, which could increase volatility of our stock price.

Any of these factors or a combination of these factors could have an adverse impact on our business, financial condition and results of operations.

We are dependent upon the industry sectors we service, which produce electronic products that are technologically advanced with short life cycles, and our business could be negatively impacted by economic slowdowns in these sectors.

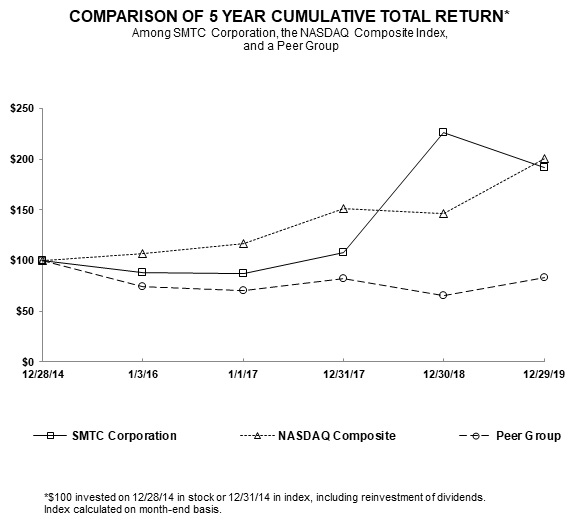

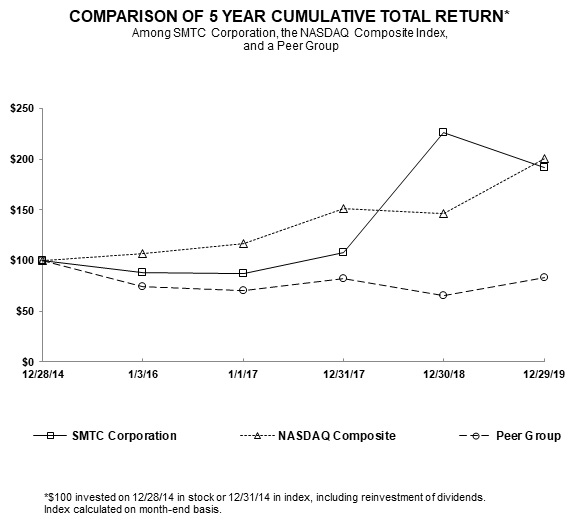

Most of our customers develop technologically advanced electronic products, which are characterized by intense competition, short product life cycles and significant fluctuations in product demand. In addition, these products are generally subject to rapid technological change and product obsolescence. If our customers are unable to create products that keep pace with the changing technological environment, their products could become obsolete and, in turn, the demand for our manufacturing services could significantly decline. Our success is largely dependent on the success achieved by our customers in developing and marketing their products. Furthermore, the electronics industry is subject to economic cycles and has, in the past, experienced downturns. A decline in the industry demand for these products would likely have an adverse impact on our business, financial condition and results of operations.